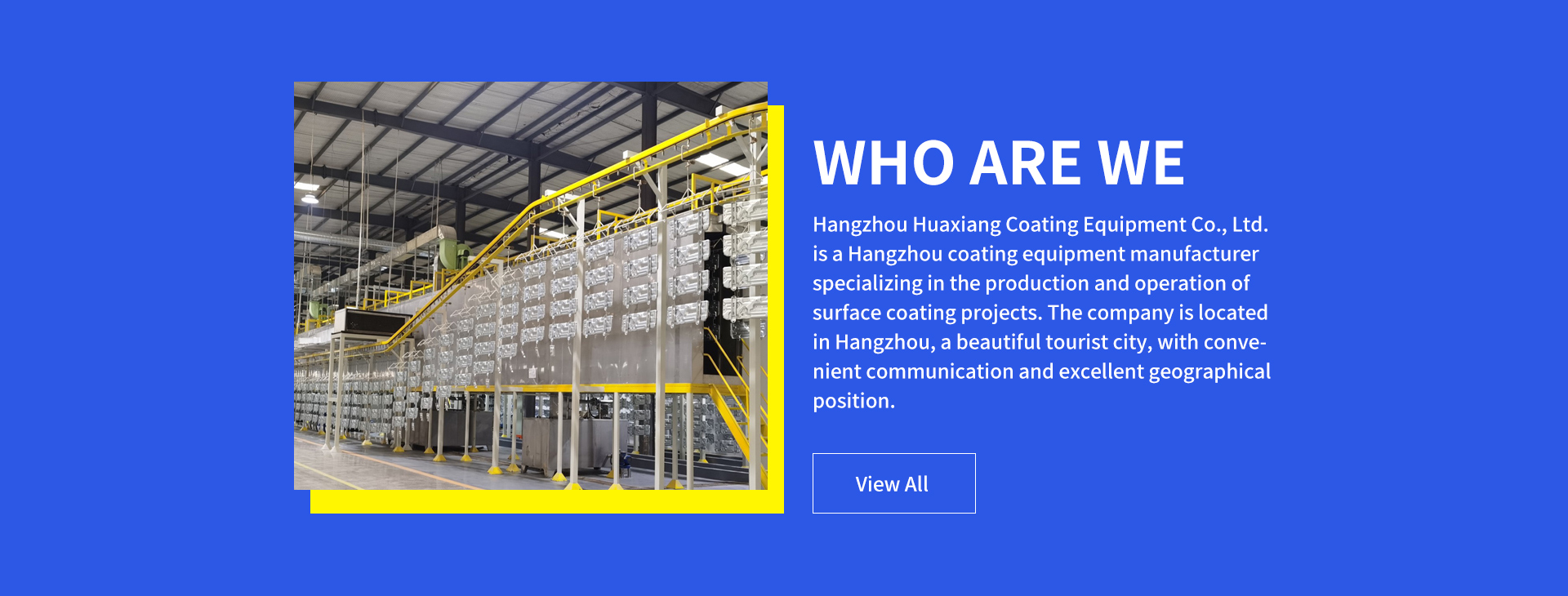

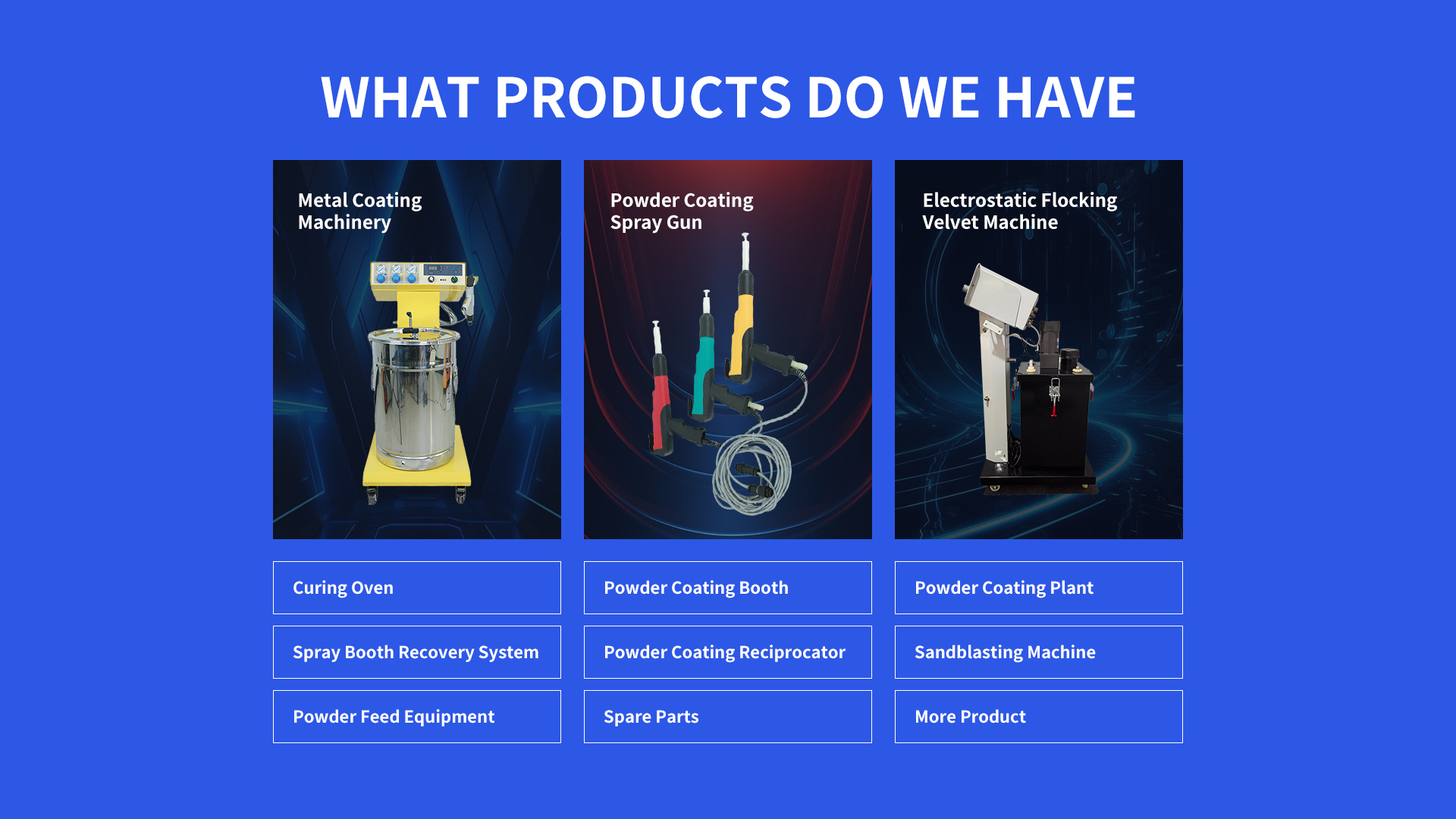

1. Powder Coating Spray Booth Equipment Overview

A Powder Coating Spray Booth is an enclosed workspace designed to contain overspray, improve coating quality, and ensure operator safety. Key components include a powder recovery system (cyclone or cartridge filters), exhaust fans, LED lighting, and grounded walls to prevent static buildup. Booths are typically made of stainless steel or powder-coated steel for durability. Advanced models feature automatic cleaning systems and adjustable airflow controls.

2. Powder Coating Spray Booth Applications

These booths are essential in automotive refinishing, industrial machinery manufacturing, and furniture production. Small benchtop booths (4–6 ft) suit workshops coating bike frames or tools, while large industrial booths (10–20 ft) handle automotive parts, agricultural equipment, and aerospace components.

3. Powder Coating Spray Booth Price Range

Portable benchtop booths: 1,500–5,000 (ideal for DIYers).

Mid-size industrial booths: 8,000–25,000 (common in repair shops).

Custom large-scale booths: 30,000–100,000+ (with high-efficiency filters and automated recovery).

Additional costs include installation (2,000–10,000) and filter replacements (200–800/year).

4. How to Use a Powder Coating Spray Booth Correctly

Ground the booth and workpiece to prevent electrostatic discharge.

Set airflow to 100–150 ft/min for optimal powder containment.

Wear PPE (respirator, gloves, coveralls) to avoid inhalation risks.

Clean filters weekly to maintain airflow efficiency.

Dispose of waste powder according to environmental regulations.

5. How to Choose the Right Powder Coating Spray Booth

Workshop size: Match booth dimensions to your workspace and part sizes.

Production volume: High-volume users need booths with 95%+ powder recovery rates.

Budget: Prioritize UL/OSHA-compliant models with warranties (1–3 years).

Energy efficiency: Look for variable-speed fans to reduce power costs.

6. Powder Coating Spray Booth Safety Precautions

Install explosion-proof lighting and motors in flammable environments.

Ensure proper ventilation to keep airborne powder below OSHA’s 5mg/m³ limit.

Regularly inspect electrical systems and grounding connections.

Train operators on emergency shutdown procedures for fire risks.

7. Design Rationality of Modern Powder Coating Spray Booths

Top booths maximize efficiency with vertical airflow designs that minimize overspray. Modular panels allow easy expansion, while stainless steel interiors resist corrosion. Energy-saving features like heat recovery systems cut operational costs by 15–20%.

8. Powder Coating Spray Booth FAQs

Q1: How often should I replace spray booth filters?

A: Replace cartridge filters every 300–500 hours; cyclone filters last 1–2 years.

Q2: Can I retrofit an old booth with powder recovery?

A: Yes—add-on recovery systems cost 3,000–10,000 depending on booth size.

Q3: What airflow speed ensures even coating?

A: Maintain 100–150 ft/min to balance powder containment and application precision.

Q4: Are used powder coating booths worth buying?

A: Yes, but inspect filters, fans, and structural integrity to avoid hidden repair costs.

Q5: How to reduce energy consumption in spray booths?

A: Use variable-frequency drives (VFDs) on fans and LED lighting for 20–30% savings.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com